Vision Driven, Mission Specific, Results Proven: the New World of Polymer in Firearms Production

OutdoorHub 04.29.14

American Built Arms Company builds firearms components with proprietary polymers using the latest breaking design technologies

Polymer in firearms production is no new news to anyone, yet the methods of manufacturing polymer gun parts has not changed in over twenty years. That is until a young, veteran-owned American company took a now popular concept and material and turned everything about polymer gun parts on its head. American Built Arms Company (A*B Arms) is a company built on a question, rather than an answer. The question came to Jason Combs, an Army vet, member of the 504th Parachute Infantry Regiment in the legendary 82nd Airborne Division and founder of A*B Arms, “How can I make the M16 handguard more heat resistant, more comfortable, more functional than what is standard Army issue?”

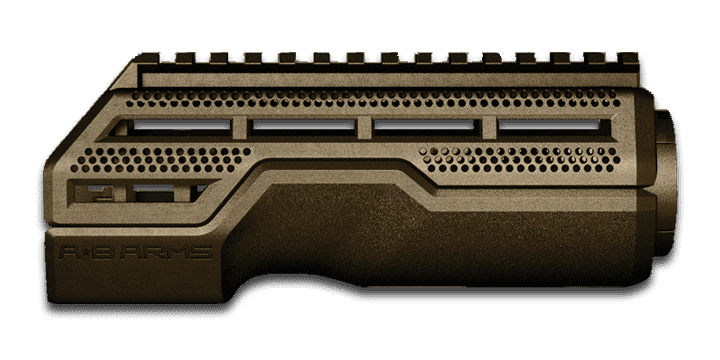

Several design concepts later, Combs tapped long-time friend, Adam Edelman for advice. Through another colleague, the first prototype of the A*B Arms MOD1 Hand Guard was born and American Built Arms Company was poised for success. The difference between an A*B Arms MOD1 Hand Guard and A*B Pro Hand Guard for AR15/M16 rifles and anything else on the market is obvious. Besides the ergonomics, lightweight and strength capabilities, one of the predominant features of all A*B Arms hand guards is the ability to dissipate heat, thus eliminating the need for a vertical grip.

The hand guard’s unique two-piece design features an upper and lower heat shield that dissipates the heat through the sides of the unit, thus eliminating the “mirage effect,” commonly found on hand guards that lack an upper heat shield.

The purpose built, ergonomic hand guard also has a hand grip area with a hand stop and a textured surface for a sure grip without the use of gloves or under less than ideal environmental conditions. The original design accommodates gas piston or direct gas impingement systems. The A*B Arms Pro Hand Guard is available in black, flat dark earth, MULTI-CAM and OD green. MSRP starts at $40.99. The MOD1 Hand Guard features the A*B Arms Mil-Spec rail system integrated on top of the hand guard, also made from lightweight polymer material reinforced with high strength fibers. This is also available in the same array of colors as the A*B Pro Hand Guard with a starting MSRP of $40.99.

A*B Arms also produces Mil-STD Picatinny rails in 4, 5 and 7-slot configurations that will fit on a variety of competitors different hand guards. A*B Arms has also designed and developed the “Light to Fight” rail system series. These rail systems are made from technologically advanced materials that make them strong, lightweight and heat resistant. The rail hardware is molded directly into the part adding strength, durability and eliminating the need for additional mounting hardware. A*B Arms LTF Rails easily installs onto multiple weapons platforms. A*B Arms LTF Rails are available in black, flat dark earth and OD green and in combo packages starting at $20.00.

A*B Arms polymer products are different from anything else on the market today. All A*B Arms polymer products are made with a proprietary blend of a high-heat rated nylon in combination with a high-strength fiber reinforcement. Another attribute to the polymer production side of A*B Arms is their ability to take a design from concept to on-the-shelf reality in much less time than traditional manufacturers. For A*B Arms and their OEM customers, the design and prototyping is done with state-of-the-art 3D printing. Traditionally, a new product goes through several prototypes; each time changes are made, the prototype must be sent back to be refashioned until the prototype reaches the anticipated concept. This procedure is time consuming and costly, often only allowing for a small set number of prototyping rounds before the cost escalates.

A*B Arms saves time and money when it comes to polymer prototyping. Utilizing the 3D printing capabilities at one of their facilities, A*B Arms’ engineers can hold a prototype within hours of design instead of days or weeks. Tweaks and changes can be made on the spot and there is no set number of reiterations before the final design is approved. R&D costs and time-to-market are considerably slashed saving companies considerable amounts of cash and shortening the new product life cycle by many months.

Whether manufacturers are looking for new and innovative polymer products and accessories for their firearms or consumers are looking for the most advanced hand guards and Picatinny rail systems, A*B Arms is their go-to company for American-designed, American-made firearms products. Be on the look-out for exciting new products from A*B Arms in 2014.

For more information on American Built Arms Company, their products or programs for manufacturers, distributors and dealers visit, www.abarms.com. Follow A*B Arms on Facebook.